The Role of Artificial Intelligence in Predictive Maintenance

Artificial intelligence in predictive maintenance is revolutionizing the way industries manage equipment, reduce operational costs, and optimize production. Traditional maintenance strategies, such as reactive repairs or scheduled preventive maintenance, often result in unexpected downtime, wasted resources, and increased operational costs. By leveraging AI-powered predictive maintenance, businesses can anticipate equipment failures before they occur, ensuring smooth operations, maximizing asset lifespan, and improving overall operational efficiency.

Understanding Predictive Maintenance

AI Predictive Maintenance is the practice of using data-driven insights to forecast when machinery or equipment is likely to fail. Unlike reactive maintenance, which addresses issues after they occur, or preventive maintenance, which follows a fixed schedule, predictive maintenance focuses on real-time monitoring and advanced analytics to optimize repair schedules and reduce unexpected disruptions.

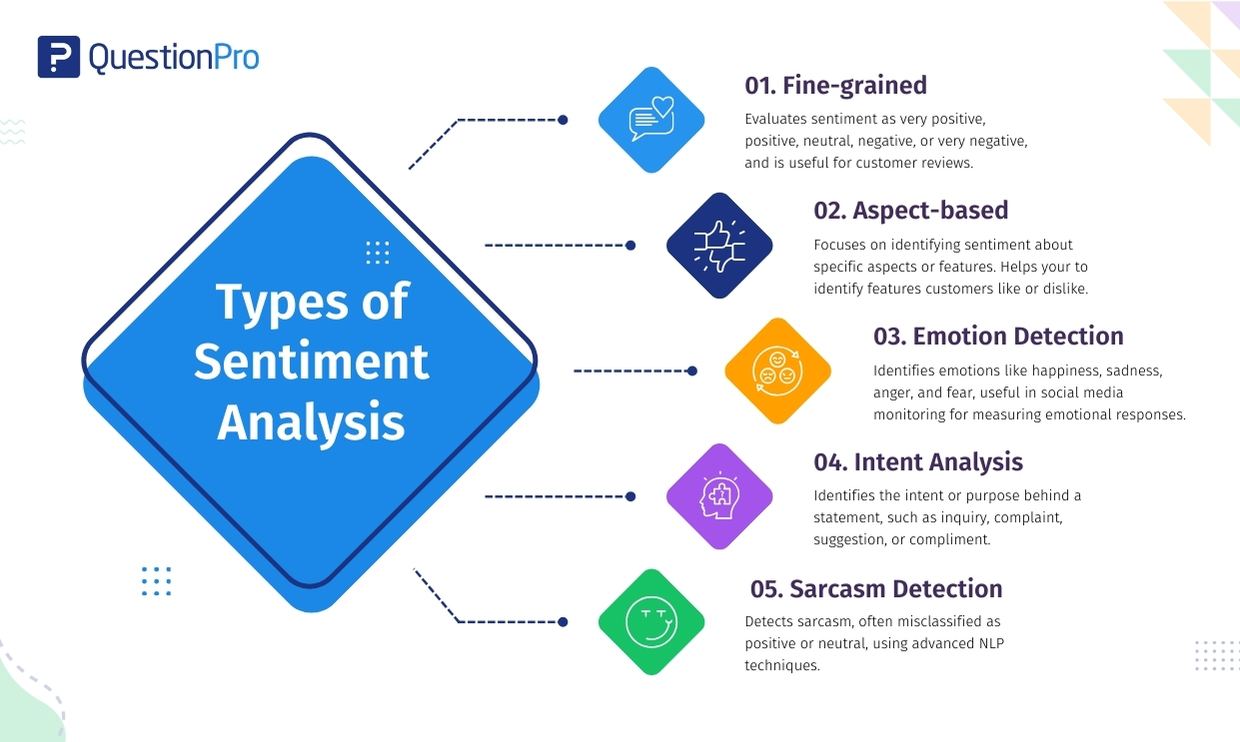

Artificial intelligence enhances predictive maintenance by analyzing vast amounts of sensor data, operational logs, and environmental variables. Machine learning algorithms detect patterns and anomalies that indicate potential failures, enabling maintenance teams to take proactive measures before issues escalate. AI systems continuously learn from new data, refining predictions over time and improving accuracy.

Applications of Artificial Intelligence in Predictive Maintenance

1. Manufacturing

In manufacturing, equipment downtime can halt production lines and result in significant financial losses. AI-powered predictive maintenance tools monitor machinery such as CNC machines, conveyor systems, and industrial robots. By detecting early signs of wear and tear, AI allows manufacturers to schedule maintenance during planned downtime, reducing unexpected disruptions, extending equipment life, and maintaining production efficiency.

2. Logistics and Supply Chain

Fleet management, warehouse automation, and transportation equipment all benefit from predictive maintenance. AI systems can monitor truck engines, refrigeration units, and conveyor belts to predict failures before they impact delivery schedules. This ensures timely shipments, reduces repair costs, and improves overall supply chain efficiency. AI-driven insights help logistics companies optimize routes, monitor vehicle health, and prevent costly delays.

3. Energy and Utilities

Power plants, wind turbines, and water treatment facilities use AI-driven predictive maintenance to optimize energy production and prevent equipment failures. Sensors collect data on temperature, vibration, and pressure, which AI models analyze to forecast issues. Early detection of potential faults allows operators to take corrective action, increasing reliability, reducing operational risks, and ensuring uninterrupted energy supply.

4. Aerospace and Automotive

In aerospace and automotive industries, predictive maintenance ensures safety and regulatory compliance. Aircraft engines, braking systems, and autonomous vehicle components are monitored in real-time using AI algorithms. Detecting anomalies early prevents catastrophic failures, improves passenger safety, and reduces operational downtime for fleet operators.

Benefits of AI-Powered Predictive Maintenance

- Reduced Downtime: By predicting equipment failures, businesses can schedule repairs during planned downtime, minimizing operational disruptions.

- Cost Savings: Avoiding unexpected breakdowns and extending equipment lifespan reduces repair and replacement costs.

- Improved Safety: AI identifies potential hazards before they become critical, enhancing workplace safety.

- Enhanced Operational Efficiency: Optimized maintenance schedules improve production output, reduce waste, and streamline resource allocation.

- Data-Driven Insights: Continuous monitoring provides actionable intelligence for better decision-making, asset management, and long-term planning.

- Sustainability: Reducing unnecessary part replacements and optimizing machine use also supports environmental sustainability goals.

Implementing AI in Predictive Maintenance

To implement AI effectively, companies should follow these steps:

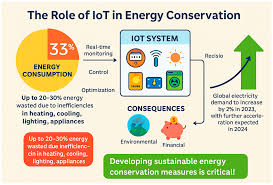

- Invest in IoT Sensors and Data Infrastructure: Collect real-time data on equipment health, performance metrics, and environmental conditions.

- Adopt Machine Learning Models: Analyze historical and real-time data to detect patterns and predict failures accurately.

- Integrate with Existing Systems: Link predictive maintenance solutions with ERP (Enterprise Resource Planning) and CMMS (Computerized Maintenance Management Systems) for seamless workflows.

- Train Teams: Ensure maintenance staff and managers can interpret AI insights and take timely action.

- Continuous Monitoring and Improvement: Use feedback loops to refine AI models, improving prediction accuracy over time.

Conclusion

Artificial intelligence in predictive maintenance is transforming industries by shifting the focus from reactive repairs to proactive, data-driven maintenance strategies. From manufacturing floors to logistics fleets and energy utilities, AI-powered tools reduce downtime, cut costs, enhance safety, and improve overall operational efficiency. Businesses that adopt AI in predictive maintenance gain a competitive edge, ensuring smoother operations, longer equipment life, and sustainable growth.

The integration of AI into predictive maintenance is not just a technological upgrade—it is a strategic investment. As industries embrace this approach, companies that leverage AI insights will enjoy higher operational reliability, better customer satisfaction, and optimized resource allocation, positioning themselves for long-term success in an increasingly competitive industrial landscape.